Engineering Underground NGL Storage for Market-Responsive Flexibility

Multi-product cavern infrastructure

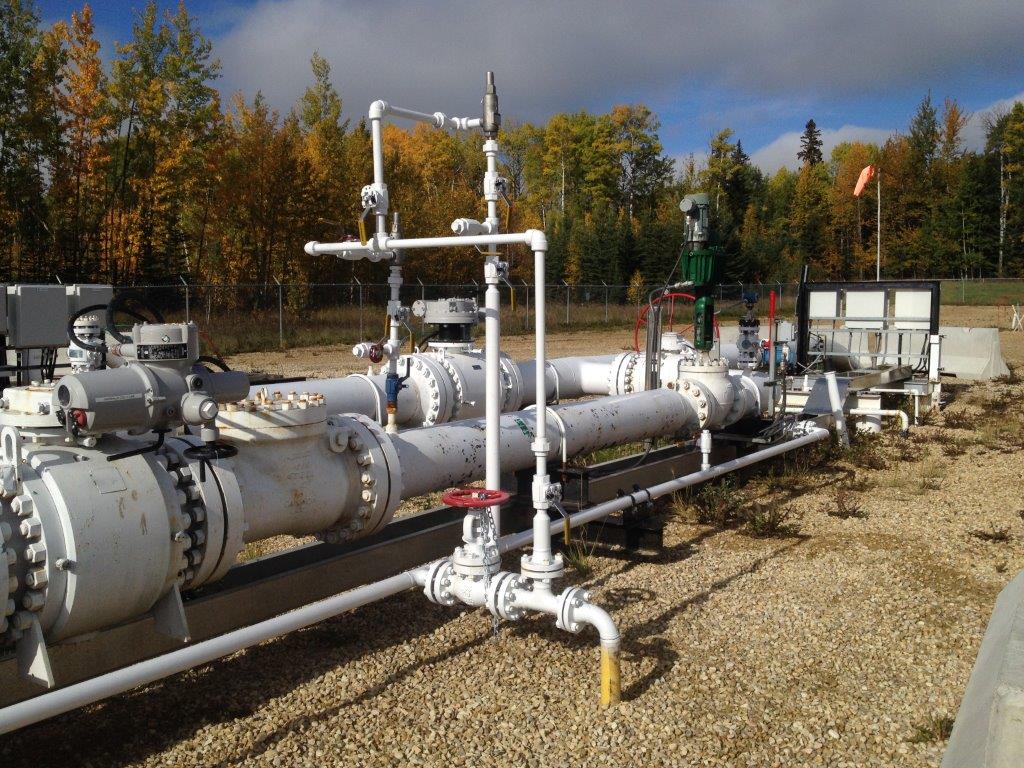

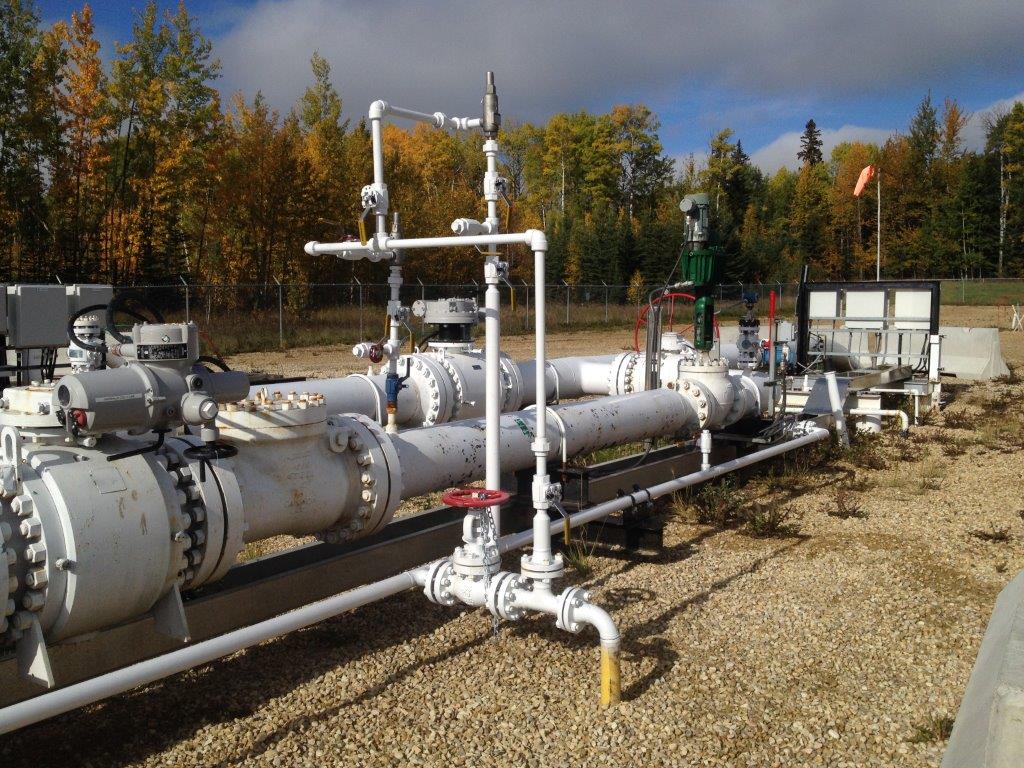

In Strathcona County, Alberta, Lauren partnered with Strathcona Storage Limited Partnership (ATCO) to pioneer the Salt Cavern Storage Facility, a greenfield expansion introducing four underground natural gas liquids (NGL) caverns totaling 400,000 m³ for the injection, withdrawal, and dehydration of ethylene, propane, and butane, bolstering seasonal supply stability in a key industrial hub. Directing multidisciplinary efforts from FEED review through detailed design and construction support in 2015-2016, our team engineered specialized power/control systems, conducted rigorous stress analyses for extreme conditions, and resolved geotechnical hurdles to deliver a resilient facility that handles cryogenic complexities and ensures safe, efficient operations in a built-up area.

Pioneering multi-product cavern infrastructure with cryogenic precision

This innovative greenfield project established comprehensive surface facilities for cavern operations, featuring two 1,750 HP propane injection pumps, two 1,750 HP butane injection pumps, two 1,250 HP ethylene injection pumps, integrated propane/butane/ethylene dehydration systems, and a hot oil package for thermal management. Lauren’s expertise extended to structural steel designs for pipe racks, tank bases, and multiple process skids, alongside cast-in-place and precast concrete foundations with finite element analysis (FEA) modeling to withstand operational loads. The scope also encompassed electrical systems including 5kV switchgear, 5kV variable frequency drives (VFDs), low-voltage motor control centers (MCCs), and PLC control panels, plus stress analyses for towers, cryogenic flares, high-pressure pumps, and piping rated up to 1500# across temperatures from -110°C to 240°C, enabling seamless NGL handling and cavern integrity.

Overcoming thermal extremes and site constraints for seamless execution

The Salt Cavern project demanded solutions for ethylene’s unique risks (spontaneous exothermic decomposition, supercritical fluid pumping, and auto refrigeration) alongside a smokeless flare for the built-up industrial zone and brine dehydration from the cryogenic flare system, which Lauren addressed through targeted process engineering and vendor collaborations. Unexpected soil conditions during pile installation in a complex geotechnical setting required on-site adaptations and FEA refinements, while cost estimations across disciplines ensured fiscal discipline. Our proactive construction management and commissioning support minimized disruptions, aligning multidisciplinary inputs to deliver compliant, high-performance infrastructure that exceeded expectations for safety and reliability.

What we delivered

Completed between 2015 and 2016 in Strathcona County, Alberta, this project showcases Lauren’s innovation in underground storage for adaptable NGL markets.

Infrastructure: Four 400,000 m³ underground NGL caverns with injection/withdrawal pumps (up to 1,750 HP), dehydration systems, hot oil package, cryogenic flare, high-pressure piping (1500# rating), structural steel pipe racks, and concrete foundations.

End-to-End Management: FEED review and development, multidisciplinary engineering including stress analysis and electrical/controls design, detailed structural/civil modeling, procurement support, and construction commissioning oversight.

Cryogenic and Geotechnical Mastery: Resolved ethylene handling challenges, soil variability, and thermal extremes through FEA, on-site adaptations, and robust power systems for operational excellence.

- FEED review

- FEED

- Multidisciplinary engineering

- Cost estimation (all engineering disciplines)

- Detailed design

- Procurement support

- Construction commissioning support

- Construction management

Related Projects

Let's Build Something

Together

Bring Us Your Challenge

Connect with our experienced team to explore solutions tailored to your goals, challenges, and timelines.

Join Our Team

We’re always looking for curious, collaborative professionals ready to shape the future of energy and infrastructure.